Industry news

Specification and model of enamel reaction kettle

The specification and model system of enamel reaction kettle (also known as enamel glass reaction kettle) is relatively complete, mainly classified according to structural form, volume range, design pressure, and stirring configuration, as follows:

1、 Structural form and volume range

1. Open type reactor (K-type)

Features: The can lid and can body can be separated, and a sealing gasket is connected through a can card for easy maintenance.

Capacity range: 50L to 12500L.

Applicable scenarios: Small and medium-sized reactions that require frequent maintenance.

2. Closed type reactor (F-type)

Features: The lid and tank body are integrally formed and require a manhole for maintenance.

Capacity range: 1000L to 50000L (up to 80000L for large equipment).

Applicable scenarios: large-scale production, reactions with high sealing requirements.

3. Other types

Micro reactor: with a capacity of ≤ 50L, suitable for laboratory high-pressure, high-temperature corrosive reactions.

Electric heating type: Integrated electric heating system, eliminating dependence on external heat sources.

2、 Core technical parameters of enamel reaction kettle

1. Pressure and temperature

Design pressure: 0.1-1.0MPa (inside the kettle), jacket pressure ≤ 0.6MPa.

Temperature resistance range: 0-200 ℃, resistant to sudden temperature changes of ≥ 200 ℃ (cold shock 110 ℃/hot shock 120 ℃).

2. Corrosion resistance and physical properties

Corrosion resistance: Resistant to inorganic acids, organic acids, and weak bases, avoiding strong bases, hydrofluoric acid, and phosphoric acid above 180 ℃.

Ceramic layer thickness: 0.2-2.0mm (main body), 0.6-1.8mm (attachment).

Insulation: The ceramic layer can withstand 20kV high-voltage spark testing.

Impact resistance: ≥ 220 × 10 ⁻ ³ J (excellent product index).

3、 Specification and Model Marking Rules

Adopting the national standards GB/T25027-2010 (K-type) and GB/T25026-2010 (F-type), the format example is as follows:

K-type mark: K ①②/③ - ④ ⑤⑥

① Design pressure (MPa)

② : nominal volume (L)

③ : nominal diameter (mm)

④ Transmission device (W/DZ/SZ type)

⑤ Blender type (anchor type M/frame type K/slurry type J/impeller type Y)

⑥ : Shaft seal (mechanical seal P/packing seal S)

Example: K0.6-2000/1300-WKP (open type, 0.6MPa, 2000L capacity, W-type transmission, frame mixing, mechanical seal).

F-type mark: F ①②/③ - ④ ⑤⑥

⑥ Expansion: Mechanical seals are divided into direct type (P) and transition plate type (PC).

Example: F0.25-20000/2800-DYPC (closed type, 0.25MPa, 20000L capacity, DZ transmission, impeller stirring, transition plate mechanical seal).

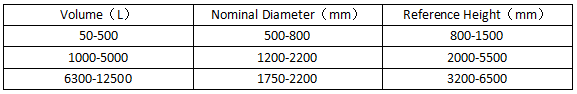

4、 Typical size reference

(Specific dimensions may be adjusted due to differences in the design of enamel reaction kettle manufacturers, please refer to the parameter table for details)

5、 Application Fields

The hydrolysis, neutralization, crystallization and other reaction processes in the chemical, pharmaceutical, pesticide, food, dye and other industries.

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province