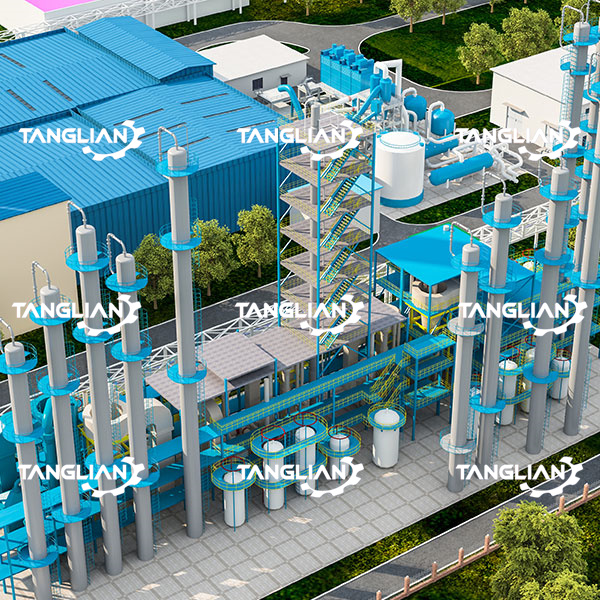

Production Line

Dimethyl Sulfoxide Production Line

SERVICE SYSTEM

1 Production technologyprocess package 2 Complete set ofproduction eguipment

3 Instructing theproduction device to start 4 Detailed constructionplan design

5 Equipment installation service 6 Personnel on-sitetraining services

We focus on providing 50+ core process packages covering the fields of basicchemicals, polymer materials, environmental protection technology, new energyand fine chemicals, and help our customers achieve efficient, safe and sustainableproduction goals with our self-developed technologies and industrialised matureexperience.

The project process packages that canbe undertaken are listed below: | |||

| 1.dimethyl sulfoxide | 2.High purity hydrogen sulphide from sulphur and hydroge | 3.Ionic membrane caustic soda project | 4.Continuous produetion ofchloroacetie acid project |

| 5.carbon disulfide | 6.Ionic membrane caustic soda | 7.Chloroacetyl chloride projec | 8.Chlorinated paraffin project |

| 9.Evaporation of solid bases | 10. Chlorinated polyethylene | 11. Sulfoxide chloride project | 12.Methyl chloroacetate project |

13.Chloroacetic aeid(eontinuous method) | 14. epichlorohydrin | 15.Ethyl chloroacetate project | 16.p/Isophthaloyl chloride project |

17.Epichlorohydrin end-use industry extension | 18.Propylene oxide Project | 19.Sodium methanol project | 20.Sulphuric acid project |

| 21.chlorinated paraffin | 22.Extended technology for the production of chlorinated paraffins | 23.Dimethyl sulphate project | 24.Glycerine-based production of epichlorohydrin project |

| 25.organosilicon | 26.Fischer-Tropsch Residue Wax | 27.Epichlorohydrin proiect | 28.water reducing agent Refining |

| 29.Polyethers,polyether polyols andpolymer polyols | 30.Separation and refining of coal-based straight-chain alkanes for the production of environmentally friendly solvent oil | 31.Fischer-Tropsch Wax Refining Project | 32. Diethyltoluene diamine (DETDA)project |

33.Stabilised light hydrocarbon deep processing project | 34. surfactant | 35.Monoalkane separation project | 36. Polyurethane project |

37.Alkylphenol project(2,4 phenol, 2.6 phenol) | 38.Antioxidants, nucleating agent | 39.Polyether polyol projects and polymerpolyol projects | 40. Alkylphenol Project |

41.Sulfoxide chloride(sulphur dioxide fumed) | 42.sulfur dioxide S02 | 43.Chloropropylene project | 44. Liquefied gas separation project |

| 45.sucralose | 46.Chloroacetyl chloride | 47.Triisoalkylaluminium synthesis project | 48.Liquefied hydrocarbons selective hydrogenation |

| 49.p/Isophthaloyl chloride | 50.Methyl, ethyl chloroacetate | 5l.Acetone Hvdrogenation to lsopropanol Projeet | 52. MTBE programme |

53.Pyridine series produets (2-chloro-5-methylpyridine, 2,3-dichloro-5-trifluoromethylpyr idine | 54.Flame retardants, organic bromine substitutes | 55. MTBE Cracking to High Purity Isobutylene Project | 56.Polymerie aluminium chloride project |

| 57. Sodium methanolate(sodiun andalkali methods are available) | 58. Sodium methanol | 59. End Amino Polyether Project | 60.High-salt wastewater evaporation project |

| 61.Dimethyl carbonate | 62. Aluminium trichloride. polymeric aluminium chloride (hydrochloric acid consumption | 63.desulphurisation and denitrification projeet | 64. Polyearboxylic acid water reducing agent project |

| 65. Terminal Amino Polyether | 66.Chlorinated Ethylene Carbonate(CEC)/Vinylene Carbonate(VC) Project | 67. Naphtha Aromatisation Project | 68. Normally Reduced Pressure Unit Proiect |

69. Diethyltoluene diamine(DETDA) project | 70.chloroform CHCl3 | 71.Asphalt plant project | 72.Gas Separator Project Project |

| 73. dimethyl ether | 74. Acid production from sulphur (HCl consumption) | 75. Diesel lydrogenation Unit Project | 76. Sulphur Recovery Unit Project |

| 77. sulfamic acid | 78.sodium pyrosulfide Na2S203(hypo) | 79. Epichlorohydrin project | 80. Ferromolybdenum formaldehyde |

81.1.4 Butanediol(BDO)/1,4 Butenediol(BED)/Propargy lAlcohol/Dimethyl Suceinate/THF | 82. dimethyl disulfide(DMS) | 83. Ionic membrane caustic soda projec | 84. Polyacrylamide, Acrylamid |

| 85.Pre-treatment of phenol-containing wastewater and recovery of ammoniaand phenol from coal/coke | 86. Continuous polyester PET plant | 87.Chloroacetyl chloride pro.ject | 88.Scrap tyre cracking |

| 89.Continuous PBT/PTT/PBAT/PBS unit | 90.Continuous polycarbonate PC unit | 91.Sulfoxide chloride project | 92.Polymer material PPC/PLA/PGA/ |

93.Continuous waste polyester reuse unit | 94. Hydrogen peroxide (anthraquinone method | 95.Ethyl chloroacetate project | 96. Acetonitrile and high purity acetonitrile |

| 97.Used lubricant regeneration | 98.Dimethyl sulphate project | 99.Sodium methanol project | |

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province