Industry news

Production process of glass-lined equipment

The reason why glass-lined products are widely used in chemical, pharmaceutical, pesticide, dye, light industry, food, metallurgy and national defense industrial systems is because of the excellent performance of glass-lined products, such as sealing reliability, higher durability, most corrosion resistance, and easy installation and maintenance.

You may not know much about the production process of glass-lined equipment. Let's briefly introduce it to you.

After checking the final version of the equipment information with the customer, we use dedicated glass lined steel plates for tank blanking. First, the equipment head is fabricated, and then the tank drum is rolled.

After that, the treated steel parts are placed on the measuring tool for welding (including head nozzle welding, tank head welding, upper and lower joint ring welding) to make their appearance shaped. After that, polishing and blank inspection shall be carried out.

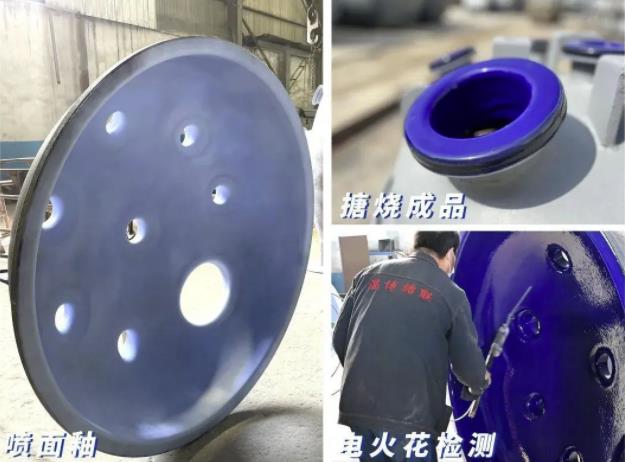

After polishing and cleaning the surface of the metal steel billet, the billet is sprayed with glaze. The glaze needs to be sprayed for 6-7 times to ensure its uniform thickness meets the standard, and then enters the resistance furnace for enamel heating. After being burned, it is cooled naturally in the room and then tested by electric spark detector. The qualified products are machined into qualified spare parts, and the jacket can be welded after passing the inspection; Unqualified products shall be returned to the glazing process for reprocessing.

After welding the jacket, it is also necessary to conduct a hydraulic test. After passing the test, the surface shall be processed for assembly. After assembly, it shall be sprayed in the paint spraying room, and then dried to be the finished product.

The above is a brief description of the production process of glass-lined equipment. If you have any questions, please leave a message in the comment area for discussion~

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province